Image 1 of

Image 1 of

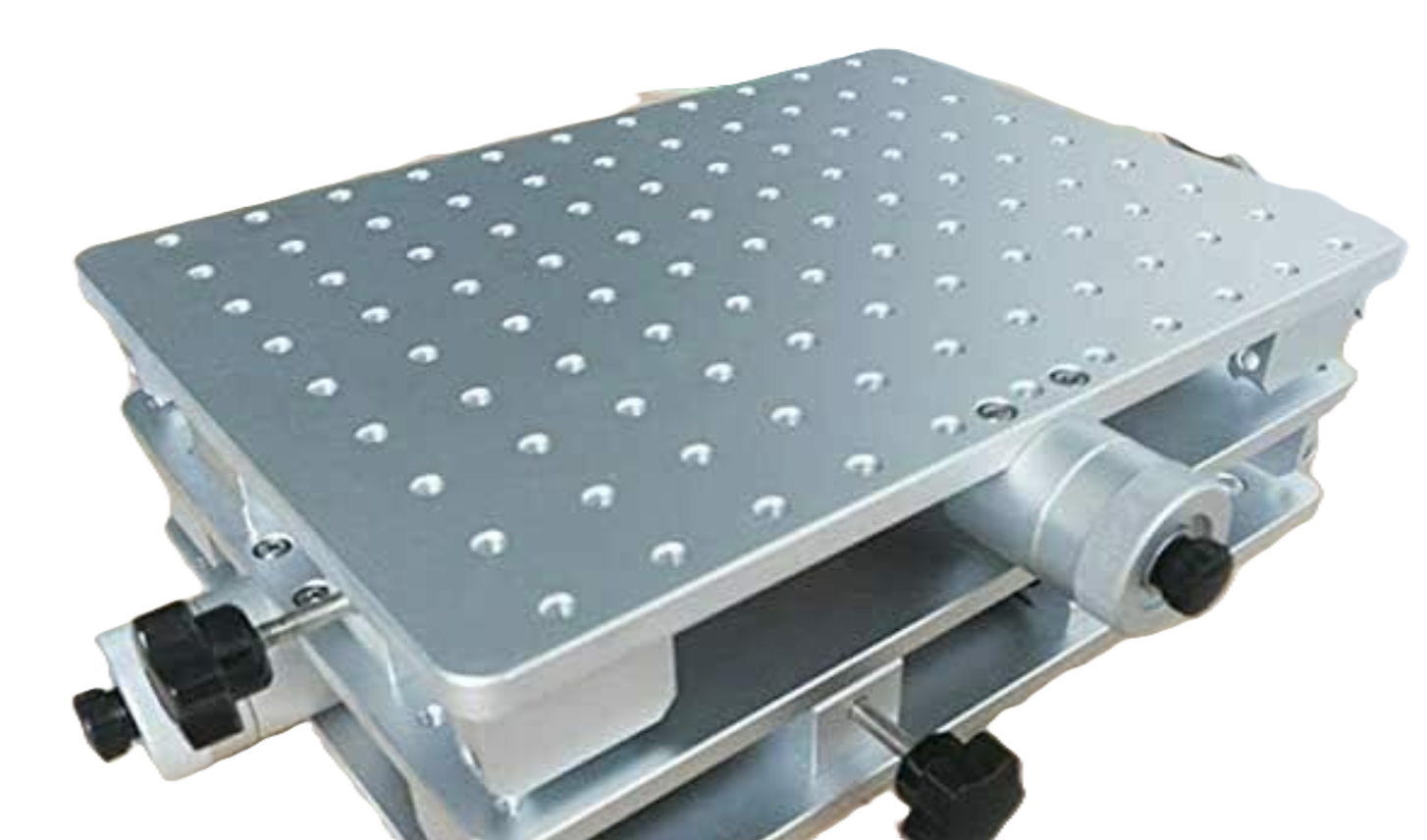

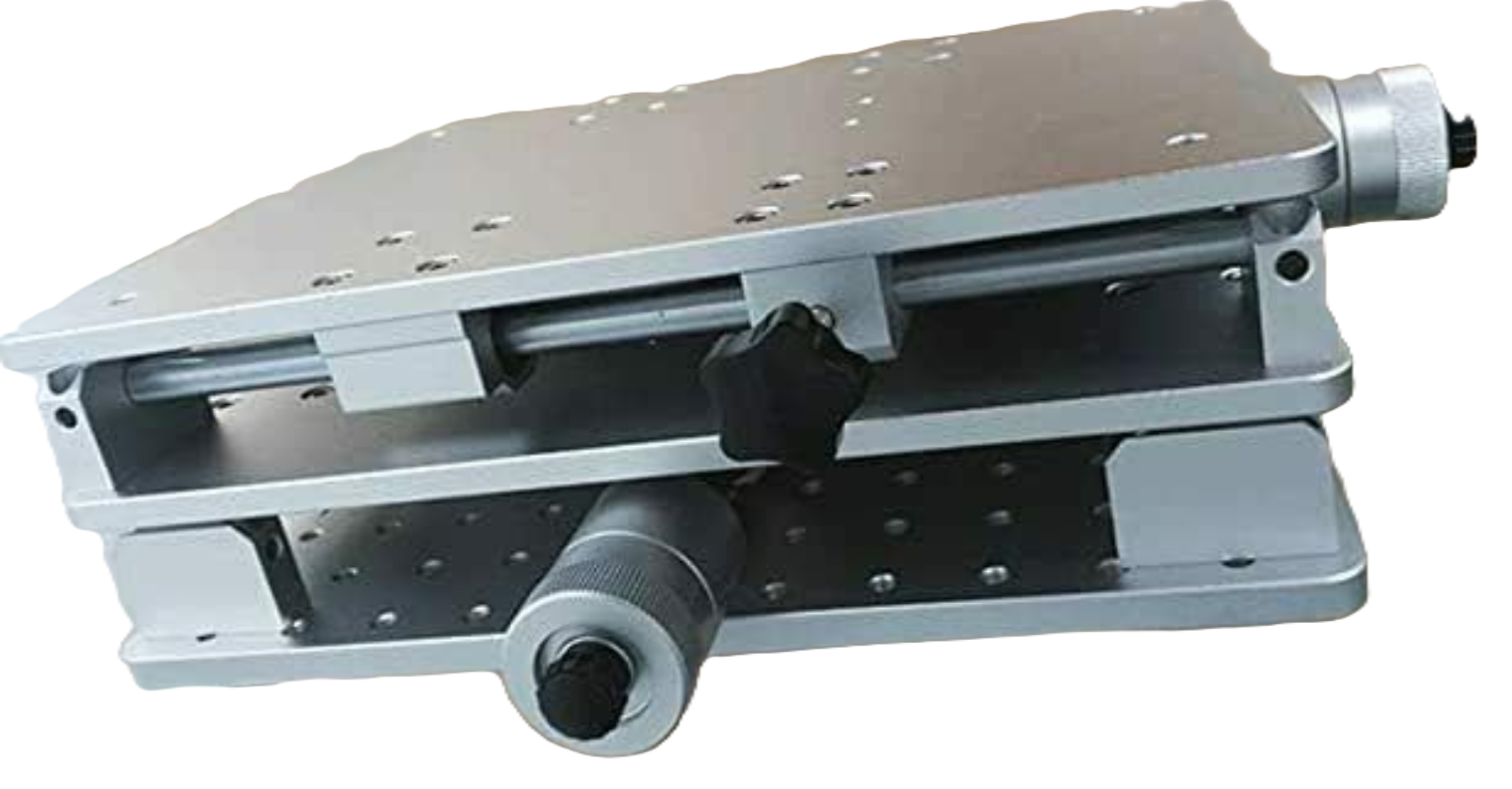

Cutting Plate for Laser Marking Machine

A cutting plate, also known as a cutting bed or cutting table, is an essential component in laser cutting systems, providing a stable and heat-resistant surface for material processing. In fiber laser marking machines, the cutting plate serves as the base upon which materials are placed during the engraving or cutting process.

Key Features of Cutting Plates for Fiber Laser Marking Machines:

Material Composition: Typically made from high-quality, heat-resistant materials such as stainless steel or aluminum, ensuring durability and longevity under high-temperature conditions.

Design: Often features a honeycomb or slotted design to facilitate efficient gas flow and debris removal during the cutting process.

Size and Compatibility: Available in various sizes to accommodate different machine models and material dimensions.

Maintenance: Designed for easy cleaning and maintenance to ensure consistent performance and prevent contamination of the workpiece.

Benefits:

Enhanced Cutting Quality: Provides a stable and flat surface, contributing to precise and high-quality cuts.

Improved Efficiency: Facilitates optimal gas flow and debris removal, reducing the risk of material contamination and improving cutting efficiency.

Extended Equipment Life: Protects the underlying machine components from heat damage and debris, potentially extending the lifespan of the laser system.

Applications:

Metal Processing: Ideal for cutting and engraving metals such as carbon steel, stainless steel, aluminum, and brass.

Non-Metal Processing: Suitable for processing non-metal materials like plastics and composites, depending on the machine's capabilities.

A cutting plate, also known as a cutting bed or cutting table, is an essential component in laser cutting systems, providing a stable and heat-resistant surface for material processing. In fiber laser marking machines, the cutting plate serves as the base upon which materials are placed during the engraving or cutting process.

Key Features of Cutting Plates for Fiber Laser Marking Machines:

Material Composition: Typically made from high-quality, heat-resistant materials such as stainless steel or aluminum, ensuring durability and longevity under high-temperature conditions.

Design: Often features a honeycomb or slotted design to facilitate efficient gas flow and debris removal during the cutting process.

Size and Compatibility: Available in various sizes to accommodate different machine models and material dimensions.

Maintenance: Designed for easy cleaning and maintenance to ensure consistent performance and prevent contamination of the workpiece.

Benefits:

Enhanced Cutting Quality: Provides a stable and flat surface, contributing to precise and high-quality cuts.

Improved Efficiency: Facilitates optimal gas flow and debris removal, reducing the risk of material contamination and improving cutting efficiency.

Extended Equipment Life: Protects the underlying machine components from heat damage and debris, potentially extending the lifespan of the laser system.

Applications:

Metal Processing: Ideal for cutting and engraving metals such as carbon steel, stainless steel, aluminum, and brass.

Non-Metal Processing: Suitable for processing non-metal materials like plastics and composites, depending on the machine's capabilities.

A cutting plate, also known as a cutting bed or cutting table, is an essential component in laser cutting systems, providing a stable and heat-resistant surface for material processing. In fiber laser marking machines, the cutting plate serves as the base upon which materials are placed during the engraving or cutting process.

Key Features of Cutting Plates for Fiber Laser Marking Machines:

Material Composition: Typically made from high-quality, heat-resistant materials such as stainless steel or aluminum, ensuring durability and longevity under high-temperature conditions.

Design: Often features a honeycomb or slotted design to facilitate efficient gas flow and debris removal during the cutting process.

Size and Compatibility: Available in various sizes to accommodate different machine models and material dimensions.

Maintenance: Designed for easy cleaning and maintenance to ensure consistent performance and prevent contamination of the workpiece.

Benefits:

Enhanced Cutting Quality: Provides a stable and flat surface, contributing to precise and high-quality cuts.

Improved Efficiency: Facilitates optimal gas flow and debris removal, reducing the risk of material contamination and improving cutting efficiency.

Extended Equipment Life: Protects the underlying machine components from heat damage and debris, potentially extending the lifespan of the laser system.

Applications:

Metal Processing: Ideal for cutting and engraving metals such as carbon steel, stainless steel, aluminum, and brass.

Non-Metal Processing: Suitable for processing non-metal materials like plastics and composites, depending on the machine's capabilities.